- Home

- Expediting 3D printed medication development using vacuum compression moulding

- Expediting 3D printed medication development using vacuum compression moulding

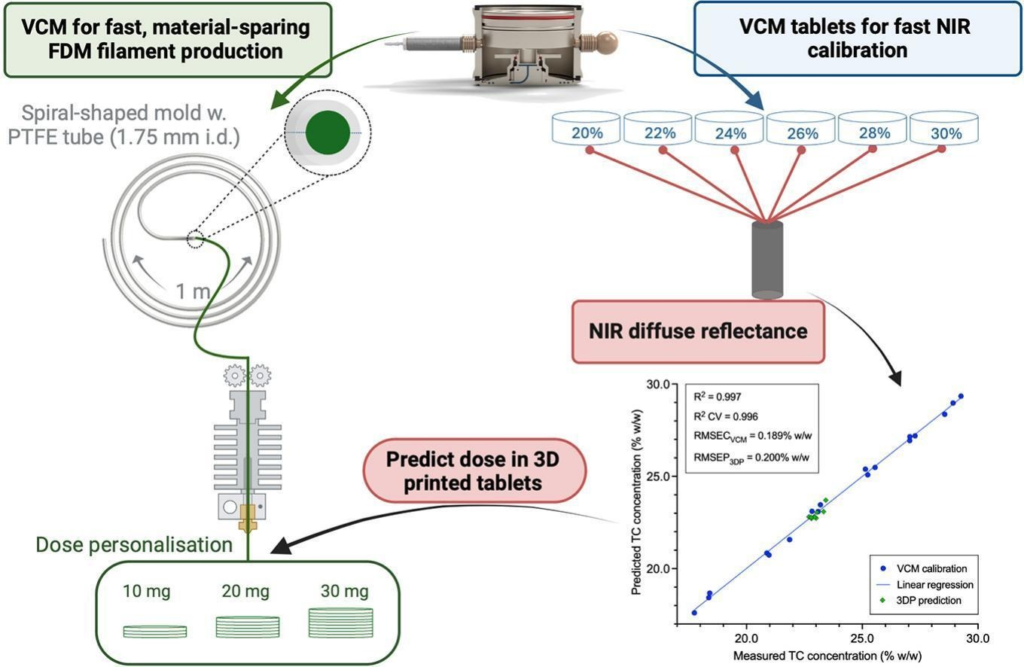

3D printing is rapidly changing the way we think about medicine—particularly when it comes to customising treatments for individual patients. One of the leading methods in this space is fused deposition modelling (FDM), a technique that prints tablets (printlets) layer by layer using drug-containing filaments. But producing those filaments with consistent quality is no easy feat, and checking the final tablet’s drug content without destroying it? Even trickier.

That’s where this study steps in. We explored vacuum compression moulding (VCM)—a more compact and efficient process—to produce high-quality drug-loaded filaments and develop a faster way to verify tablet drug loadings.

Using tamoxifen, a drug used in clinical trials for 3D printed medications, we printed tablets with precise doses of 10, 20, and 30 mg. Even better, the use of VCM-made samples to build a non-destructive near-infrared (NIR) model could accurately predict the drug content in real 3D printed tablets — no sample preparation required.

This method shows real promise for faster, greener, and more reliable development processes for 3D printing of personalised medicines. By combining the strengths of VCM and FDM, the future of truly customised healthcare is getting closer.

Curious about how this could impact patient care soon? Read more here.